Get Support

123-456-789-10

Nextcore Electronic Co.,Ltd Solenoid Factory Tour

Production Line

OEM/ODM

R&D

| Machinery/Production Process Our factory has 6 production and assembly lines. Our production process is 30% fully automated, 40% semi-automated and 30% manual. The equipment used for production are mostly imported. Some of the machines used for production include:

Aeesmble Line  Raw Materials Warehouse  Injection Dept  Hardware Turning Process Dept  Stamping and Die Dept |

For our Tooling Department, Hardware & Plastic Injection Molding Department, Contact Department, Equipment Manufacturing, Machining Department, we are procuring increasingly more equipment to meet production needs for more quantity, efficiency and better quality for our customer OEM/ODM requirments.  CNC processing Center  Milling Machine  In addition to buying and importing heavy and advanced equipment from outside, we have also set up our own organization specializing in improving parts manufacturing and product assembly devices and equipment. With the many semi-automatic and full automatic specific purpose devices and machines made by our own Equipment Department, we have greatly improved the production efficiency and consistency; the quality and the stabilization of the products are all reliably insured. |

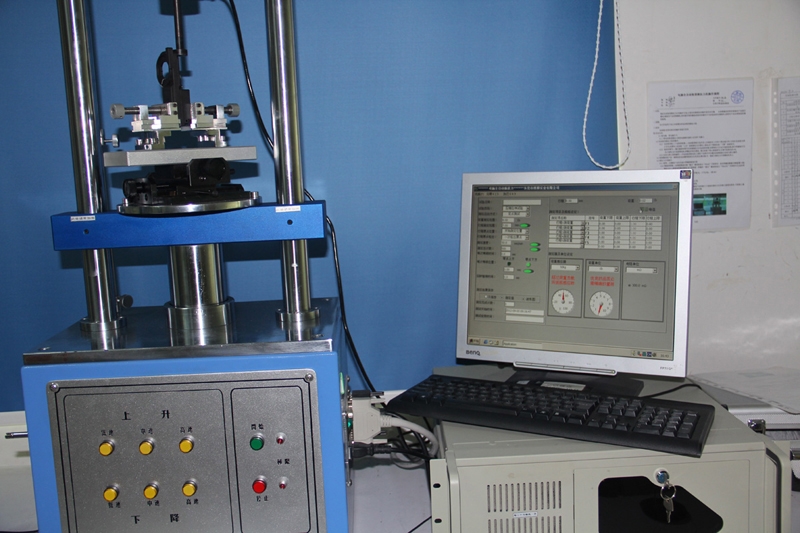

| Nextcore Electronic provides R&D and quality management with reliable tools and means. Our factory boasts of the comprehensive and advanced, testing and inspecting devices, instruments and equipment in our Laboratory of 200 square meters. The lab can conduct solenoid valve, solenoids and their parts, material performance and reliability test according to IEC and national standard. It is also a lab in conformity with TUV requirements for relays testing.   |

By: admin

By: admin