Get Support

123-456-789-10

- Performance (at initial value):

- Voltage: 24V+/-10%

- Resistance: 90 Ohm +/-10%

- Insulation grade: class B (130 degree Celsius)

- Lead wire: class A (105 degree Celsius)

- Temperature rise: 80 degree Celsius (at continuous duty,ambient temperature 40 degree Celsius, with heat sink)

- Insulation resistance: more than 100MΩ on a 500V DC megger (at normal temperature and normal humidity)

- Dielectric strength: 1,000V AC, 50/60Hz, 1 minute (at normaltemperature and normal humidity)

- Operating temperature range: -20 to 40 degree Celsius

- Life expectancy:

- Standard life: 2,000,000 cycles or more

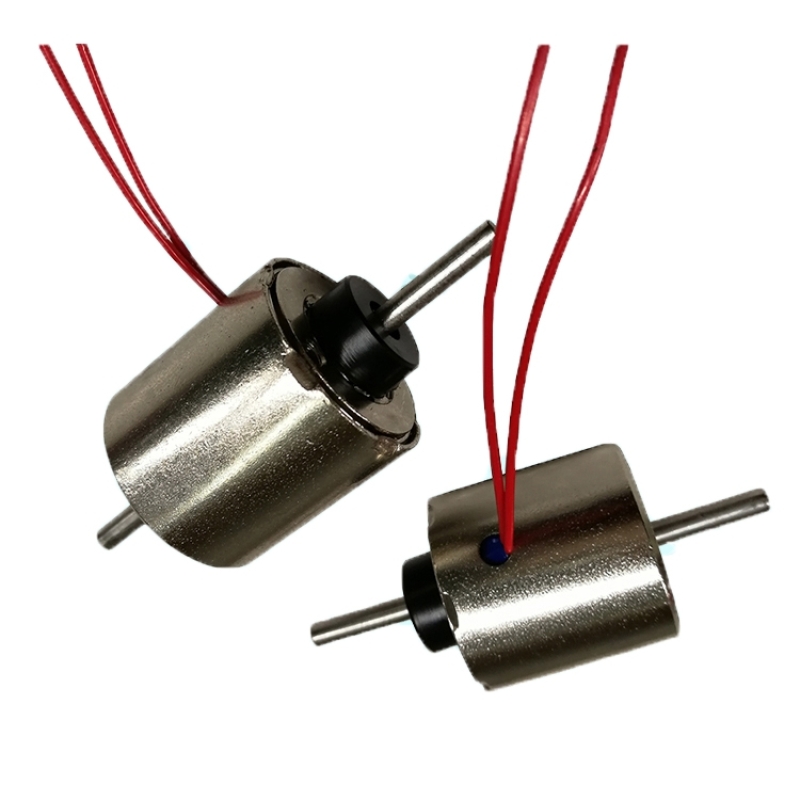

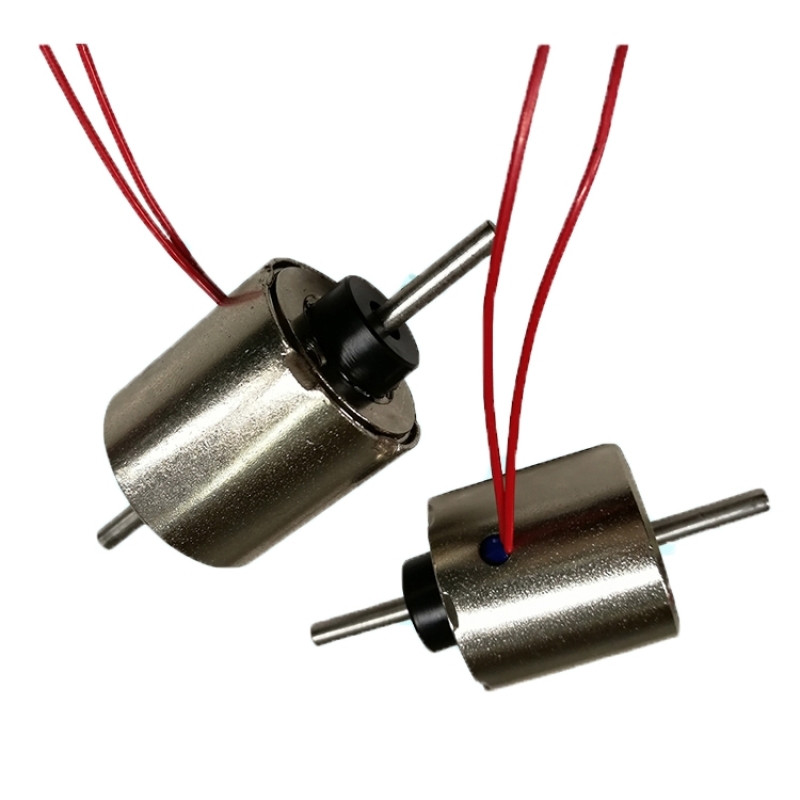

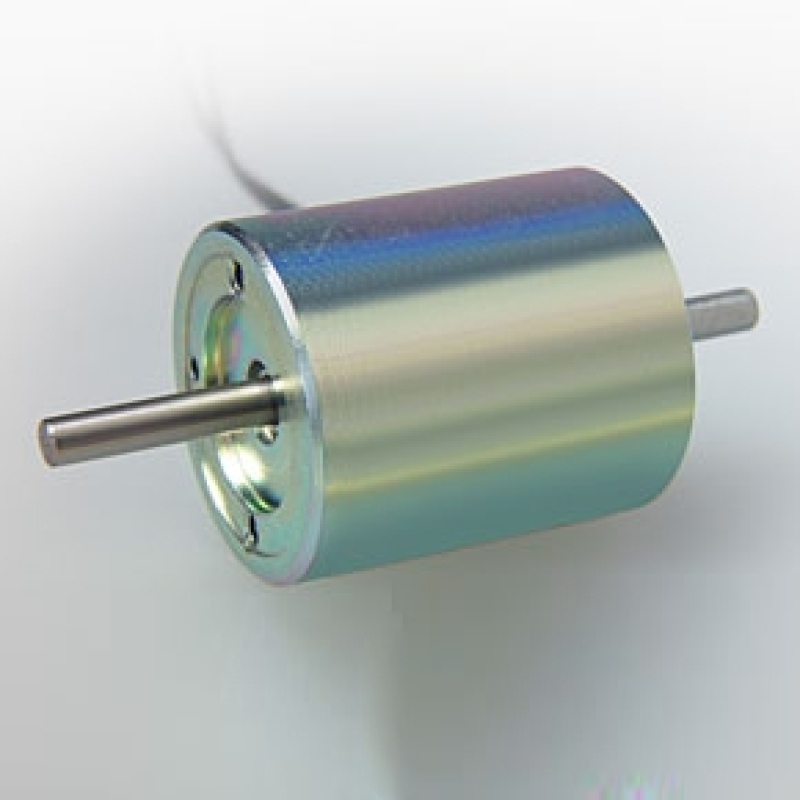

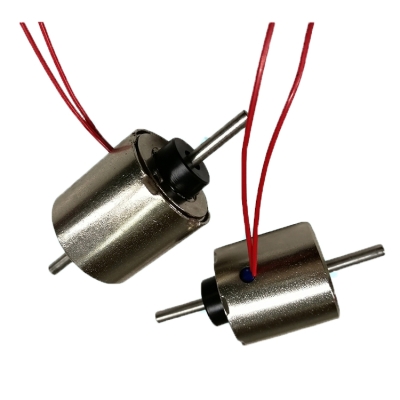

- Design and features: the rotary solenoid’s design starts from ainternal plunger flat face of push-pull solenoid

- The rotary solenoid then incorporates the mechanical designprinciple of an inclined plane to convert linear motion to rotarymotion

- There are three uniform inclined planes (spiral grooves) thatare stamped into both the body and the armature, call ballrace

- The ball race provide both a means of converting linearmotion

- to rotary motion and a secondary bearing system to support thisrotary motion (fig. 1)

- The all races are specially designed and provide a constanttorque output

- Please refer to the duty cycle vs torque graph to checkdifference torque output

- The rotary solenoid uses an enclised coil and thereforeprovides maximum magnetic efficiency

- The magnetic circuit is very short, so high efficiencies interms of torque output can be obtained, and energize/response timesa very quick